Discover the Creativity of In-Mold Decorations in Manufacturing

Discover the Creativity of In-Mold Decorations in Manufacturing

Blog Article

Grasping In-Mold Decorations: Approaches, Patterns, and Ideal Practices for Ideal Outcomes

In the world of manufacturing, the art of in-mold decors stands as an essential aspect of product style and manufacturing. As industries constantly seek cutting-edge methods to boost aesthetic charm and performance, understanding the ins and outs of in-mold decorations has become a vital ability. From selecting the ideal products to integrating sophisticated design fads, the trip towards attaining optimal outcomes in this domain is multifaceted. By diving right into the strategies, patterns, and ideal techniques that underpin effective in-mold decor processes, services can open a world of possibilities that not just boost the visual allure of their products but also streamline manufacturing performance and bolster customer engagement.

Material Choice

Material choice is a vital aspect of grasping in-mold decorations, as it directly influences the quality and sturdiness of the last product. When picking products for in-mold designs, it is essential to take into consideration aspects such as compatibility with the molding procedure, the preferred visual outcome, and the ecological conditions the product will certainly encounter.

Moreover, the chosen material needs to possess excellent adhesion homes to guarantee that the design adheres strongly to the substrate throughout the molding procedure. Adhesion between the product and the decoration is essential for protecting against delamination and guaranteeing durable visual allure. Furthermore, products with high warmth resistance are preferred for in-mold designs, especially for items that will certainly be exposed to elevated temperature levels throughout their lifecycle. By carefully choosing the appropriate material for in-mold decorations, makers can boost the total quality and durability of their items, satisfying the assumptions of both clients and end-users.

Layout Innovation

A vital aspect in advancing the field of in-mold decorations is the continuous exploration and implementation of design innovation techniques. Layout technology plays a critical duty in boosting the visual charm, functionality, and overall top quality of items made making use of in-mold design processes. By including ingenious style aspects, producers can differentiate their items out there, draw in consumers, and remain ahead of competitors.

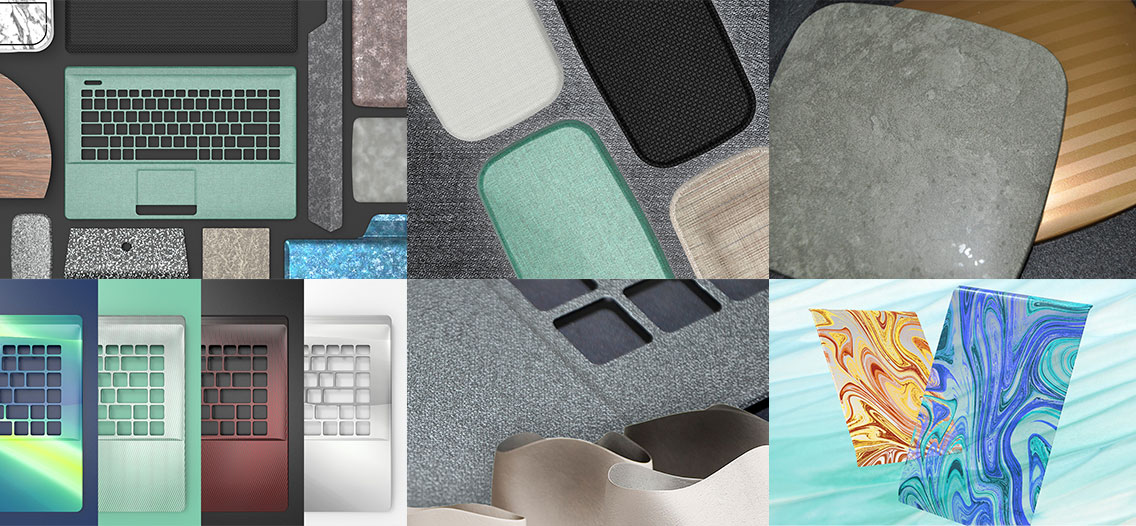

Among the crucial aspects of layout development in in-mold designs is the assimilation of complex patterns, appearances, and graphics that were previously challenging to achieve with standard decor techniques. Advanced innovations such as 3D printing and digital layout tools make it possible for developers to produce complex and in-depth designs that can be flawlessly transferred onto molded components. Furthermore, making use of vivid colors, metal finishes, and unique results like gloss or matte structures can even more boost the visual charm of in-mold enhanced products.

Additionally, layout development expands beyond aesthetic appeals to encompass practical enhancements such as ergonomic forms, integrated attributes, and customizable components that deal with particular customer demands. By embracing layout technology, suppliers can unlock brand-new opportunities for item, personalization, and imagination differentiation in the affordable landscape of in-mold decors.

Manufacturing Performance

Efficient production procedures are essential for equating the cutting-edge layouts created in the field of in-mold designs right into high-quality completed items that fulfill market needs and customer assumptions. In the world of in-mold decors, manufacturing performance includes numerous vital facets that add to the total success of the production procedure. One crucial element is the optimization of mold and mildew layout and tooling to ensure smooth and precise design transfer onto the last product. By fine-tuning mold setups and buying high-quality tooling materials, producers can improve efficiency and consistency in manufacturing.

Automation not just increases the production procedure yet also improves precision and repeatability, leading to a much more top quality and uniform end item. On the whole, a holistic approach to production efficiency is extremely important in optimizing the possibility of in-mold decor strategies and attaining optimum outcomes in the affordable market landscape.

Top Quality Control Measures

What are the key techniques for guaranteeing strict high quality control steps in the world of in-mold designs? Quality assurance measures are critical in in-mold decoration processes to ensure the manufacturing of remarkable and high-quality ended up items. One important technique is the application of extensive evaluation Discover More Here protocols at every phase of the production process. This entails carrying out complete aesthetic evaluations, dimensional checks, and color uniformity evaluations to identify any kind of inconsistencies or issues early.

Utilizing sophisticated technologies such as computerized evaluation systems can additionally enhance the quality assurance procedure by providing precise and trusted data for analysis. These systems can identify blemishes that may be missed out on by manual assessments, therefore improving overall product high quality and consistency.

Routine training and growth programs for employees included in the in-mold decoration process can additionally contribute to preserving high-quality standards. By informing team on best practices, quality expectations, and the relevance of attention to detail, business can promote a society of top quality consciousness throughout the company.

Customer Allure

To enhance the marketability of in-mold decoration items, catering and understanding to consumer preferences play an important function in identifying their charm and success. Customer allure in in-mold decors is affected by numerous variables, consisting of layout aesthetics, shade selections, durability, and overall functionality. Consumers are increasingly looking for individualized and unique products that reflect their originality and design. Using modification alternatives such as tailored designs, shade variants, and textural aspects can substantially enhance the charm of in-mold design products.

Final Thought

In-mold decors supply a reliable and flexible way to enhance product visual appeals. Mastering in-mold decors needs an all natural method that considers all facets of the production process to ensure success.

In the world of manufacturing, the art of in-mold decorations stands as a pivotal facet of product design and production. Layout advancement plays view it an important role in boosting the aesthetic appeal, capability, and general quality of items produced using in-mold decor processes.One of the vital elements of design innovation in in-mold designs is the integration of detailed patterns, structures, and graphics that were formerly challenging to attain with conventional design methods.Reliable production procedures are important for translating the innovative layouts developed in the field of in-mold designs into top notch finished items that fulfill market demands and customer assumptions. Using customization choices such as personalized styles, shade variations, and textural aspects can dramatically enhance the allure of in-mold design products.

Report this page